PULSES FLOURS IN THE BAKERY FOOD

Some financial newspapers defined them “superfood” that are becoming the leder in the market and food industry thanks to proteins and soluble fiber nutritional features. That is why we tried to understand possible applications and advantages that pulses flours can provide to some categories of bakery food.

Thanks to their gelatinizing property, the pulses flours found a wide use in the dry pasta production but they can be olso used as clean-label ingredient to replace chemically or biotechnologically starch modifiers, emulsifiers and sugar.

An interesting application, that enhanced their gelling properties, allow us to use them in the frozen bakery food or pre-baking. The gels of the pulses flours showed a good stability at freezing or de-freezing cycles and they ensure a great crust as well as the same time a soft crumb to a final product.

Thanks to ability to give softness to frozen products, pregelatinized pulses flours are used also in the bakery food (sandwich bread, tortillas and sliced bread) or sponge-cake with long shelf-life to keep an extended soft crumb even after possible ri-baking.

Pulses flours are natural hydrocolloids with emulsifier property and that’s why they are considered important ingredients in the gluten-free bakery products.

Thanks to this emulsifing property they can be used in many recipes, where we need to replace or reduce protein concentrates, emulsifiers, starches, and hydrocolloids.

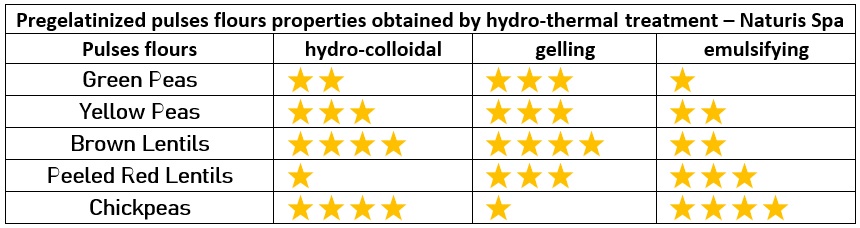

The pulses flours have different properties and so it is important to choose the right variety, typology or mix, to achieve the maximum performance. The process of production of pulses flours has an important influence on their performance. The particle size, fiber content, gelatinization grade are parameters that have to be evaluated in function of the goal that we would like to achieve.

Each pregelatinized pulse flour has hydro-colloidal, emulsifying and gelatinization different parameters as shown in the following table.

Maximum optimizing of the pulses flours can be reached by different ways of processing or kneading. Their maximum hydration will be very important to exploit the maximum emulsifier property.