PREGELATINIZED PULSES FLOURS IN GLUTEN-FREE FRESH PASTA

In the last World Pasta Day 2020, important issues, such as innovation, sustainability, ethics, globality and nutrition were discussed. The ingredients, that today certainly satisfy all those issues, are the pulses flours.

Today pregelatinized pulses flours are key ingredients in the gluten-free fresh pasta production to achieve, not only nutritional targets (proteins, fibers, especially soluble fibers), but also to achieve performance goals and clean label. They are optimal natural hydrocolloids and excellent emulsifiers.

Today pregelatinized pulses flours are key ingredients in the gluten-free fresh pasta production to achieve, not only nutritional targets (proteins, fibers, especially soluble fibers), but also to achieve performance goals and clean label. They are optimal natural hydrocolloids and excellent emulsifiers.

In the gluten-free fresh pasta, their hydrocolloid effect is key for the consistency of the doughs.

The fact that they are excellent emulsifiers enhances the viscoelasticity of the doughs .

The viscoelasticity of the doughs is an important property for in the production of certain shapes of fresh pasta to achieve the best performance of the product.

According to the original pulse, every pulse flour has a different starch gel that reacts differently to temperature and heating time; this is very important to diversify the products and to solve overcooking and texture problems.

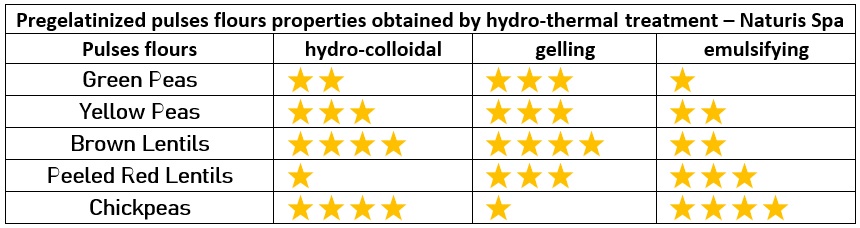

Particle size, fiber content and degree of gelatinization, are the basicl parameters to differentiate pulses flours and to determin their effectiveness and efficiency from a hydro-colloidal, emulsyfing and gelling point of view. Thus, not only the raw material can make the difference, but also the technology with they are processed (hydro-thermal or mechanical treatment) may enhance some properties at the expense of others.

Each pregelatinized pulse flour has hydro-colloidal, emulsifying and gelatinization different parameters as shown in the following table.

These characteristics are important to understand which is the best blend to ensure the performance of our final product or better replace or reduce a certain ingredients in our recipes.

These characteristics are important to understand which is the best blend to ensure the performance of our final product or better replace or reduce a certain ingredients in our recipes.

When using the pulses flours in the preparation of pasta doughs the temperature of ingredients and of water will determine a difference in the performance of the flours; accelerating or delaying the complete hydration of the flour particles. An incomplete hydration of the flour particles will reduce the hydrocolloidal power and emulsifying effect of the pulse flour.

When making a dough the order in which we process the ingredients will affect the final result, that is why there for it is a necessary condition to use them in the order that guarantees the best hydration and therefore the best performance of the pulses flours.