THE MOLD ON THE BAKERY FOOD AND PASTA IS A MATTER OF THE AIR QUALITY

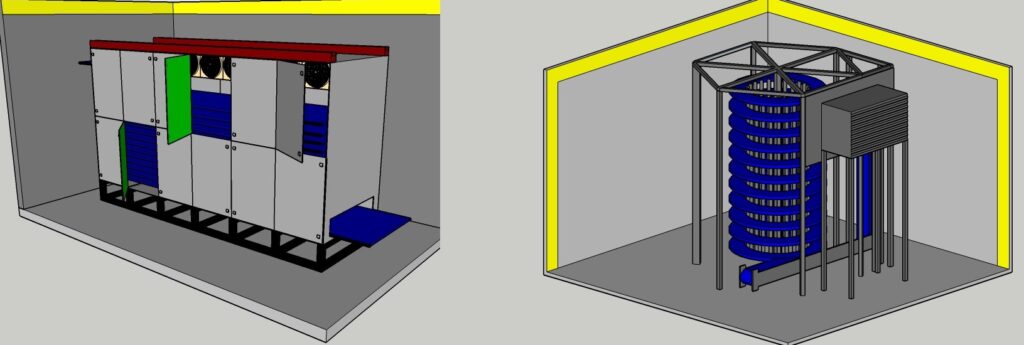

From our experience we understood that a critical point, important for the fresh pasta, pre-cooked pasta and bakery food, with high levels of water activity (sandwich bread, tortillas, sliced bread, baguette, pre-baked bread, croissants, brioche, sponge cake and plum-cake), could be the cooling system.

The cooling system could be the zone where, after the pasteurization, recontamination happens as a result of moulds. Production lines, with high product capacities and nearly hermetic conditions could be new sources of contamination. Air used in the cooling system, if not systematically sanitized during the various production cycles, could become a dangerous concentrate of bacteria that contaminates the products before packaging.

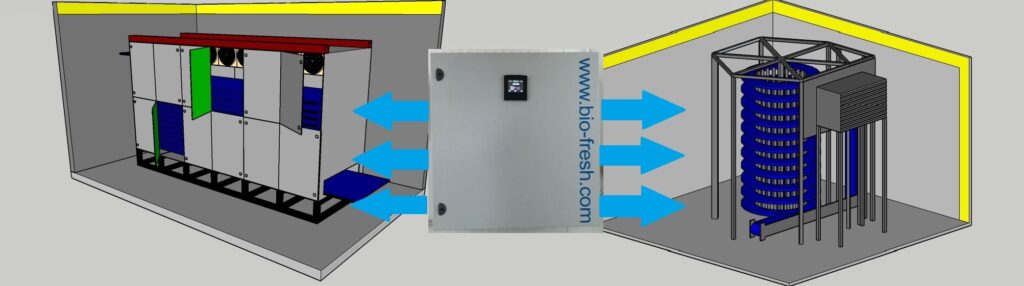

Unfortunately, the mould stays in the air and so normal sanitization done by contact liquids, fumigants or dry fogs is not able to ensure complete sanitization of the cooler equipment. So we insert a small piece of equipment to generate Ozone, near the cooler, to sanitize the air which is used to cool the product.

Unfortunately, the mould stays in the air and so normal sanitization done by contact liquids, fumigants or dry fogs is not able to ensure complete sanitization of the cooler equipment. So we insert a small piece of equipment to generate Ozone, near the cooler, to sanitize the air which is used to cool the product.

The systematic sanitization of the air is essential, not only for the air that circulates internally in the cooling system or in the packaging environments, but also for the air that could enter for compensation from other external environments with probably microbiological qualities unknown. Filters and UTA, if not frequently sanitized, are often not enough to guarantee air quality.

The safety of the application of ozone gas is guaranteed by the process and security sensors placed both inside and outside the plant. The sensors guarantee not only safety, but also considerable versatility in creating sanitation protocols at different ozone concentrations. Furthermore, sanitizing with known and controlled Ozone concentrations protects the structures and machinery from any oxidative risk.

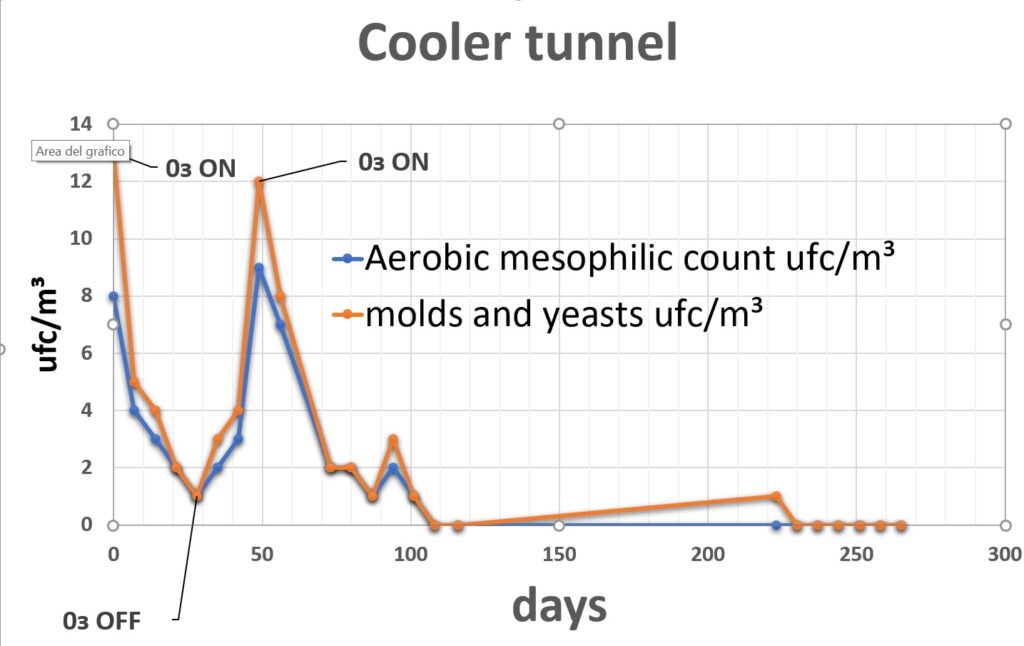

The following graph shows how a constant Ozone sanitization reduces progressively and drastically bacteria and mould concentration of the air.

The frequency of use and concentrations of ozone will be fundamental to maintain aseptic environments. The sanitization of the production, transfer and packaging areas is often difficult to plan, organize, and execute with efficacy if it is carried out with normal fumigants, fog generators or contact liquids. Thanks to this system you can program the sanitization at any time, without additional costs and residues. It is a highly effective and efficient technology because the treatment is ensured by the correct concentration of the ozone and the possibility of reaching hidden and elevated points (example: filters, air ducts and ceilings). The practicality of this technology allows frequent sanitization and so the microbiological healthiness of the processing environments at any time of the year.

Today ozone is widely used also in the sanitization of silos and drying rooms for pasta. The action of the Ozone gas is effective, not only at a microbiological level, but also at an entomological level. Ozone spreads in all spaces, and that is why it is very effective in reducing the development of eggs, larvae and insects that can secondarily contaminate the finished product.

Today an ozone solution is a sustainable choice because the gas is self-produced, thanks to the concentration sensors, is not wasted, it has a high energy efficiency and reduces the use of fumigants and chemicals.

This technology is considered a technological innovation and so it could benefit of tax discounts.